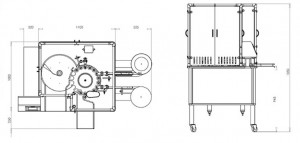

VERSATILE – COMPACT

VERSABLOCK is a compact versatile full featured monoblock for the automatic filling, plugging and capping of your products under sterile conditions or not. Thanks to its design it fits to small rooms and is very easy to operate and clean. VERSABLOCK can handle a wide range of products, and has been designed for quick changeover. Basic models are available for glass or plastic vials and for any kind of closures. The standard pumping system supplied is a peristaltic pump equipped with a Watson Marlow pump head that allows rapid transition from the laboratory to production. Options such as seal-less piston pumps, laminar flow hood, and castors for full mobility are available when required.

Product dosing is controlled by a Watson Marlow 505L peristaltic pump. The pump is stepper motor driven, fully controllable from the operator interface panel (H.M.I.). Filling needles are mounted on a descending nozzle mount, which is synchronized with the starwheel indexing. A vial presence sensor at the entrance of the starwheel monitors the presence of incoming containers. In case of missing vials, a warning signal will sound and the machine will stop.

Optionally, alternate peristaltic pumps, or seal-less piston pumps may also be incorporated depending on each application.

A second filling station is added to reduce filling time on larger containers. Containers are half filled under each filling head.

Automatic plug and cap sorters, and feeders, with automatic pick and place systems can be added to the basic machine even years after initial purchase. This provides ultimate flexibility and reduces the investment with low production volumes. Some components can be automated and others hand placed.

A plug and cap presence sensor is placed before the closure area to monitor the presence of plugs and caps. In case of missing plugs or caps, a warning signal will sound and the machine will stop.

Pre-threaded caps are electronically tightened allowing controlled application torque. The vertical motion of the capping head is synchronized with the starwheel movement. Aluminum crimp caps are sealed using a three roller crimping head, a four roller head is used for ROPP caps.

Standard features include:

- Stand Alone Design, mounted on castors

- All stainless steel construction

- Fully guarded for operator protection

- Stainless steel Infeed turntable with integral loading shelf

- Allen Bradley PLC

- HMI touch screen control with 2 level password access

- Output up to 40 per minute depending on fill volume

- Vial presence / machine stop sensor

- Watson Mariow 505L Peristaltic pump drive

- Cap presence / machine stop sensor

- Separate final torque station

- One set of container and cap change parts included

- Stainless Steel accumulation shelf

- Instruction manual

Options:

- Second filling station with descending needle

- Seal-less piston filling (316 SS)

- Fully automated plug feeding with dedicate change parts for quick change over

- Pick and place system for plugs

- Fully automated cap feeding with dedicate change parts for quick change over

- Pick and place system for caps

- Different capping heads available

- Additional Change parts

- Possibility of tray loading

- CIP/SIP capability

- Laminar flow hood

- CFR 21 Part 11 compliant Induslrlal PC

- IQ/OQ documentation

- Further options on request